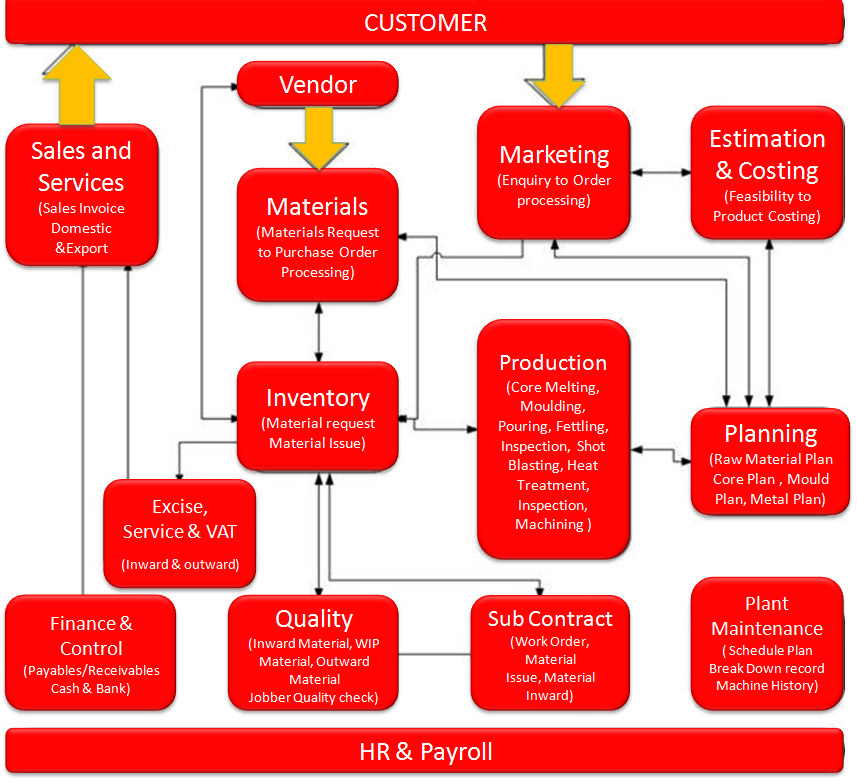

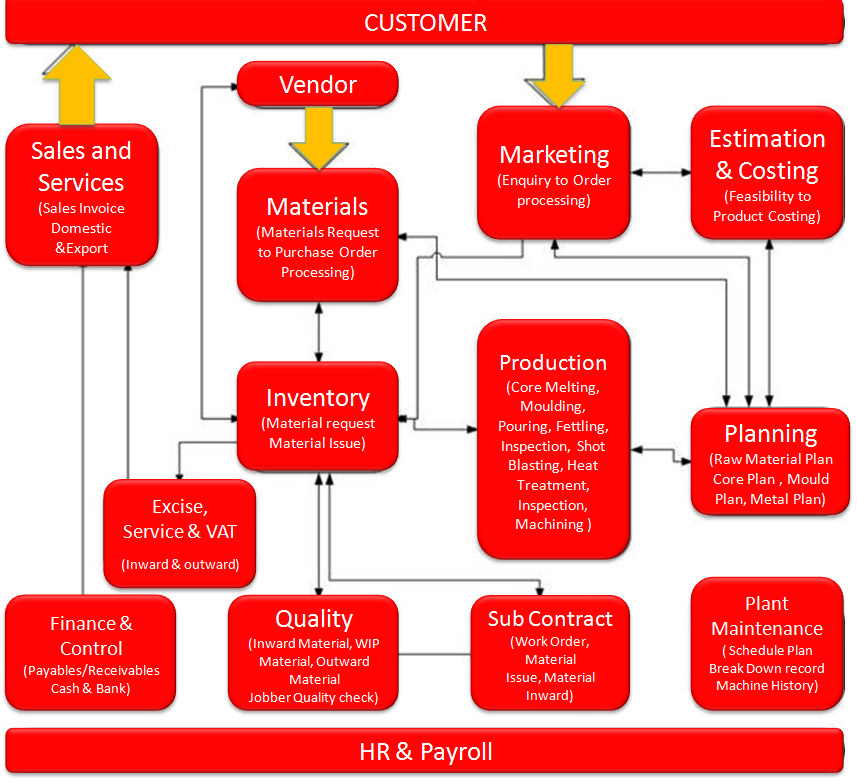

Challenges faced by foundry industries is to meet on time customer delivery schedules, reduce quality cost (rejection), better & efficient energy utilization, inventory carry cost and labor utilization.

etEngine-Foundry ERP specifically designed & implemented in 50 major foundries across India, enabled with best practices of Foundry Industries to meet the above challenges

Foundry specific solutions

- Product costing

- Tool to estimate the product cost for better quote with 99% accuracy

- Tool to compare the actual cost of production to ensure profitability

- Complete production planning solution to know

- Capacity utilization & bottleneck analysis of Moulding, Melting & Core making

- Raw material planning for better ‘just in time inventory’

- Scheduling of shop floor (modeling line) to meet customer deliveries

- Complete foundry shop floor solution to know

- Daily production log, line with planning

- Rejection Analysis-Heat/ Product / Defect wise

Why etEngine for Foundry Business

- Exclusively foundry business management solution with 50+ implementation

- Detailed Estimation & costing module for product cost analysis

- Exclusive “planning module” for Melting, moulding & core making dept.

- Heat-wise tracking of customer END rejection with detailed compiled

one access summary of Melting, pouring, quality

- Tracking of product development status methoding, pattern, core box with history card

- Easy Casting Weight variance analysis

- Moulding machine idle time analysis-Better utilization of capacity

- Casting defect analysis with range of parameters-Heat no, product, metal grade

- Tool development cycle time analysis

- Decade of domain expertise for the implementation team

- Successful implementation to SMEs to large scale foundries in shortest possible time